Galil Controller Used in Diagnostic CT Scan Imaging System to Assess the Structural Integrity of Corrugated Metal Pipe.

Corrugated Metal Pipe (CMP) is used in a wide variety of transportation and storm water management settings around North America. The pipes come in all different shapes and sizes for culverts, sewers, gravity drains and the like. CMP is considered a flexible conduit to engineers and as such, is reliant on the surrounding soil for the majority of its structural strength. In other words, CMP sitting on a flatbed truck can be deflected by a human jumping on it, however, properly surrounded with soil, the structure will bear the load of a transport trailer. As time goes on, these CMP installations need to be assessed to allow for proper maintenance. In the past, assessments were typically subjective, involving visual appraisals and acoustic assessment tests which can be inconclusive. The more conclusive tests used to be destructive to the actual pipe wall, which would worsen the structural integrity.

The solution to this problem was developed by Inversa Systems in 2009. The company developed the first CAT scan for infrastructure, known as Backscatter Computed Tomography (BCT), which is used to look through the CMP wall without disturbing the pipe or soil to verify if the pipe is adequately supported. A BCT scan uses backscattered gamma radiation to measure the density of a point in space relative to the adjacent points. A relative map of density is created, producing a picture of the material within the scan field. This provides an accurate, objective, and non-destructive assessment of the structural integrity of CMP and its surrounding soil. With the appropriate structural assessment, maintenance decisions are made accordingly, and rehabilitation efforts can be done at a fraction of the cost of replacing the same asset while avoiding service disruption.

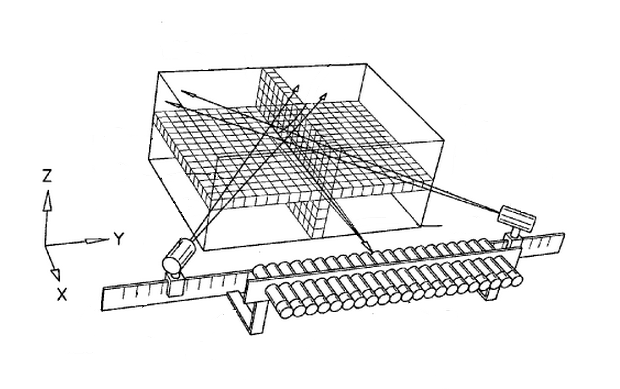

To accomplish this, Inversa Systems uses Galil's 4-axis DMC-4040 with internal two-phase drives. Two axes control two linear actuators to complete the scan. The other two axes control two rotation tables, one is the source collimator, and the other is a detector array. These two rotation tables work in tandem to provide a scan from both sides of the desired area. The source collimator will focus the scan deeper and deeper with each successive pass to provide a complete depth analysis of the structure.

As the collimated beam moves through the CMP and into the adjacent soil, it reaches a focal point that the detector collimator is aligned to receive as backscatter. The radiation count, after some initial discrimination, is sent to the Galil controller. The DMC-4040 assigns ‘x’ and ‘y’ address information based on the angle that the beam is entering the material and the distance between source and detector. The combination of count and address information allows for generation of a complete real time image of density, including the metal pipe and material around the pipe. Lack of density indicates a void space which verifies an unsupported region of pipe.

The DMC-4040 presented key features to allow for the high-performance and easy implementation and operation of the BCT scanner. The controller uses simple ASCII based communication allowing the development of a Windows-based interface to collect and distribute the data, and the integrated LCD screen on the DMC-4040 enhances the benefits of on-site troubleshooting. Lastly, the fast processing power of the Accelera controllers allows for multiple processes to run effectively in parallel using multi-threading.

With Inversa Systems' pioneering research in bringing the diagnostic capability of a medical CAT scan to infrastructure and Galil's high-performance and cost-effective motion controllers, condition assessment and asset management is possible in a setting once deemed impossible or impractical.